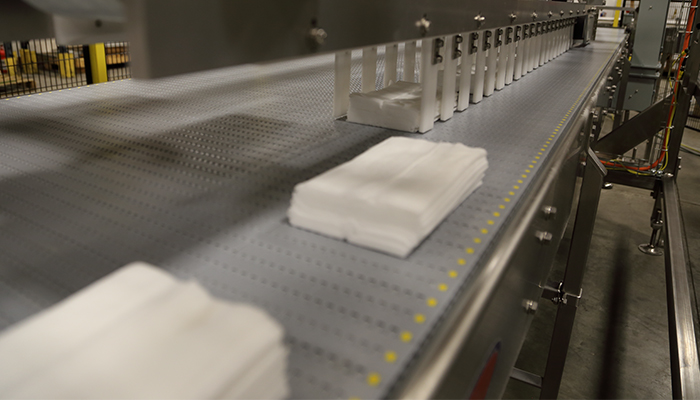

High-speed automation for folding, wetting, cutting, and piling of wet wipes presents throughput challenges when fragile stacks of newly-produced wipes are transferred to downstream primary and secondary packaging machinery operating at lower throughput speeds. Smart conveying solutions, such as Slip-Torque® roller technology, Dynamic Accumulation, SmartFeed®, and flexible product control devices – developed by Shuttleworth – enable high-speed end-of-line throughput of delicate wet wipes while maximizing uptime, minimizing product damage, and maintaining industry standards for cleanliness. Read more in the new white paper, written by Shuttleworth Sales Engineer Christian Dager.