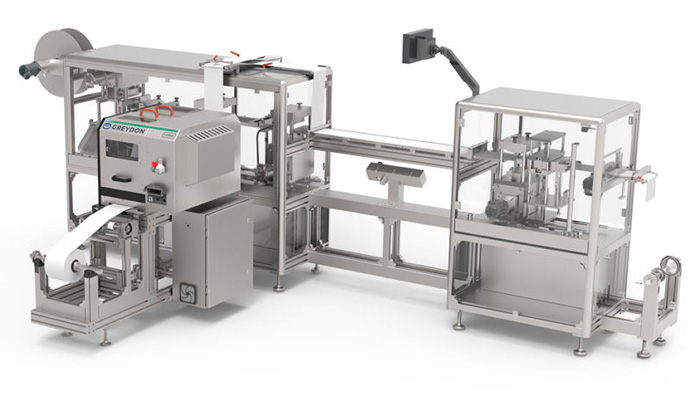

A new video from Pharmaworks shows another great example of the power of performance when ProMach product brands come together on a packaging line. ProMach product brands Pharmaworks, a leader in blister pack machinery, and Greydon, a leader in thermal transfer, digital, thermal inkjet, continuous inkjet, and code daters, work together to print variable data on blister pack backing.

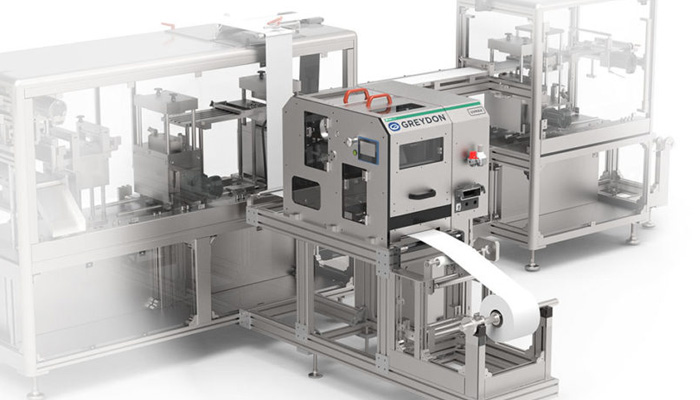

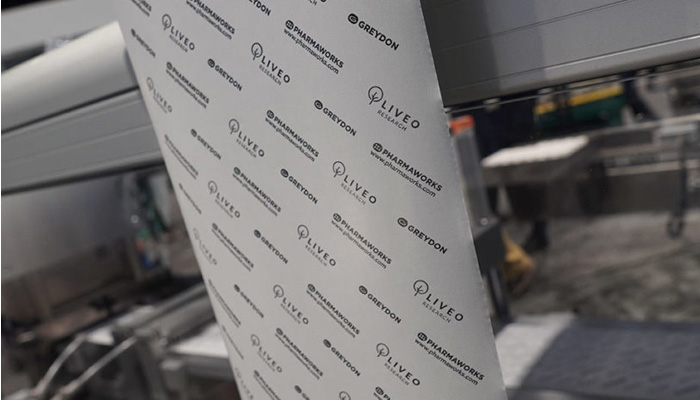

Greydon’s UVMax™ is a flexographic printing system, specifically designed for blister packaging equipment integration. The fixed information is printed using flexo technology and a thermal inkjet printer (TIJ) is included to add variable data, such as date/lot codes and DSCSA serialization barcodes. Flexographic and TIJ inks are UV-cured, providing control of the curing process.

Another value of Greydon’s UVMax™ integration with the TF1 is that this process prints on unprinted materials, which eliminates the need to store and manage pre-printed blister backing materials because the UVMax is printing right on the line, print copy changes can be done quickly, and this machine combination aids in lean manufacturing goals.

Watch the video above for the machinery in action and learn more about the UVMax™ flexographic printer here.