The retorting process is vital in the packaging world as it addresses key concerns related to food safety, convenience, sustainability, and innovation in packaging, to name a few. As demand for shelf-stable and convenient food options continues to grow, the role of retorting in food packaging is likely to become even more prominent.

In a recent blog post on Retorts, ProMach product brand Allpax takes an in-depth look into retort agitation methods and the applications and benefits of each kind. Retort processing is essential for creating shelf-stable products at room temperature for extended periods without requiring additives for preservation.

What You’ll Learn:

- Overview of Retort Processing: Retort processing involves heating food or beverage products in sealed containers at high temperatures (240°F/115°C to 270°F/132°C), exceeding traditional cooking methods.

- Heating Methods: There are three heating methods in retort processing: conduction, convection, and forced convection. The method chosen depends on the product’s properties, such as water and fat content, viscosity, and particulate size.

- Product Composition Considerations: The chemical composition of the product is crucial. Agitation is used in some cases to prevent negative effects of high heat, like the Maillard reaction (undesirable in certain products) and caramelization.

- History and Evolution of Agitation: The concept of agitation in retort processing evolved over time. Initially perfected in the mid-19th century, studies later showed that agitation reduces heating time and speeds up cooling post-sterilization.

- Types of Agitation:

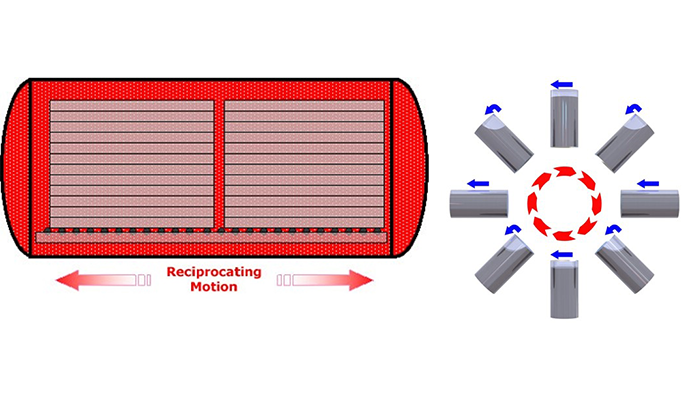

- Rotation: Axial rotation for continuous processes, suitable for steel cans, and end-over-end rotation for batch processes, accommodating different container types.

- Horizontal Reciprocation: This involves moving containers back and forth, effective for low viscosity products and those with delicate particulates. It includes the SHAKA™ method, which dramatically reduces heating and cooling cycles and is suitable for high viscosity products.

- Role of Headspace

- Benefits of Reduced Heating and Cooling Cycles

The post emphasizes the importance of choosing the right retort processing method based on the specific properties and composition of the food or beverage product, highlighting how advancements in agitation techniques have significantly improved the efficiency and quality of retorted products.