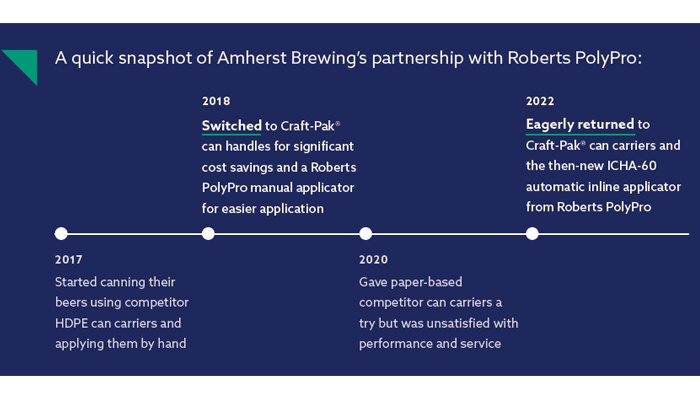

When Amherst Brewing, a local brewery in Amherst, MA, recognized the demand for their beloved beer outside of restaurants and bars, they began canning their variety of beer for customers across the state.

In their quest to find a reliable can-carrier supplier, Amherst Brewing found Roberts PolyPro, a ProMach product brand and leader in can handles and multipack solutions for bottles, cans, and more. The company was attracted to Craft-Pak® multipack carriers, which are 100% recyclable and use 30% less plastic than competitor products, are low in cost, and ensure dependability.

After a brief time away experimenting with paper can carriers, Amherst returned to the Roberts PolyPro Craft-Pak® can handles due to their reliability in protecting the can packs while being environmentally responsible.

Now that demand and production were increasing, the recognition of the grueling process of manually applying can carriers was clear. The team at Amherst upgraded from a manual process to an automatic can-handle applicator from Roberts PolyPro, the ICHA-60. This decision boosted production by 25%, cut costs, and ensured product quality and assurance.

In a new case study by Roberts PolyPro, the team outlines the decision-making process by Amherst Brewing, the evolution of their brewery’s success in product availability, and how the Craft-Pak can carriers and ICHA-60 helped boost production on all fronts.

Read and download the case study below!