Across manufacturing operations, companies are embracing new approaches to sustainability that balance operational efficiency with responsible resource use. One area where this is particularly evident is in the manufacturing processes of Ready-to-Drink (RTD) beverages and similar products that rely heavily on retort systems. These systems, essential for ensuring product safety and shelf stability, traditionally consume significant amounts of water, posing challenges for sustainability initiatives and where water resources are costly.

Retort systems are vital in food and beverage processing, providing the necessary heat treatment to eliminate pathogens and extend shelf life. However, retort operations have long been criticized for their water-intensive nature. Water serves as both a heating medium and a cooling agent, making it a primary resource in the retort process. This reliance on water can significantly drive up operational costs.

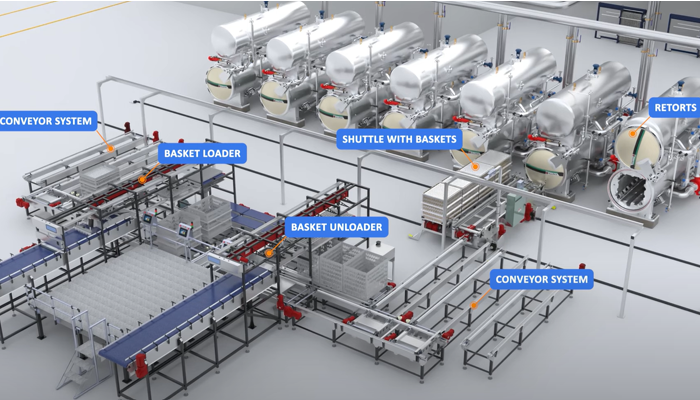

Addressing these challenges, Allpax provides their customers a closed loop water recovery system, in which they can design, build and install for new or existing retort systems. This technology represents an increase in sustainable manufacturing practices by drastically reducing water consumption in retort operations. The system’s design allows for the recovery and reuse of water, minimizing the need for fresh water inputs and drainage and thereby easing the strain on local water and water treatment sources.

Sustainability Goals in Manufacturing

Companies across industries are increasingly prioritizing environmentally responsible practices, not only to meet regulatory requirements but also to align with consumer expectations for eco-friendly products and processes.

Beyond environmental benefits, by reducing water consumption, companies can lower their operational costs associated with utilities and resource management. Demonstrating a commitment to sustainability can enhance the brand’s reputation and attract environmentally conscious consumers and partners.

Thought Leadership in Sustainability

Thought leaders in the industry recognize the importance of driving innovation towards sustainable solutions. Allpax providing complete turn-key systems for a water recovery exemplifies this proactive approach. By providing all the necessary components and methods that promote resource efficiency and environmental stewardship, Allpax can not only contribute to a company’s global sustainability efforts but can also be a partner in helping achieve these goals.

The role of sustainable innovation in manufacturing will only grow in importance. Industry leaders must continue to collaborate, innovate, and invest in technologies that not only optimize operations but also minimize environmental impact.

Watch the new video from Allpax below, where you can see each of the components of the Retort Water Recovery System in action, addressing complex industrial challenges. As industries evolve towards a more sustainable future, solutions like the Allpax system serve as signs of progress for a more environmentally conscious and economically viable manufacturing sector. And to learn more about Allpax and to discuss your project, reach out to a retort expert here.