The snack food market is experiencing an impressive boom and is expected to grow from $256 billion in 2023 to $559 billion by 2028. This phenomenal growth, averaging a 17% CAGR, is propelled by evolving consumer preferences, an increasing appetite for healthier snack options, and the ever-growing need for convenient, on-the-go nutritional solutions. Manufacturers are continuously looking for innovative products that spark customer loyalty.

Within this growing market, flexible bags and pouches have emerged as frontrunners, primarily due to their convenience for mobile snacking. This trend underscores the urgent need for manufacturers to adopt efficient, reliable packaging solutions to meet the soaring demand. In this space, Quest, a ProMach product brand and leader in industrial automation equipment focusing on robotics and vision guidance, offers the Quik Pack QP200 robotic case packer, which stands out as an ideal solution, particularly for products packaged in flexible materials.

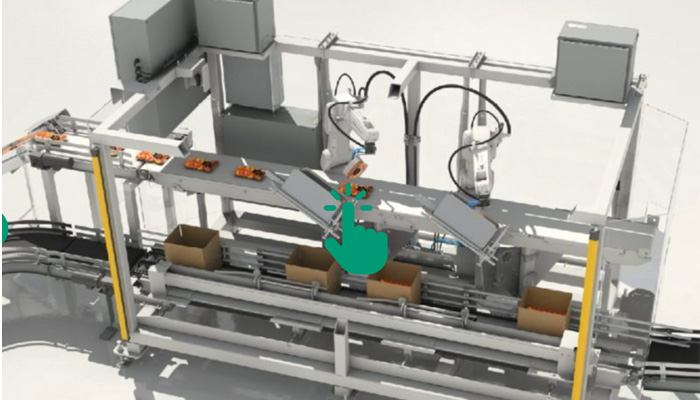

The Quest Quik Pack QP200

The Quik Pack QP200, a robotic top-load case packer from Quest, is engineered for optimal performance with products in flexible packaging. This equipment excels in identifying, tracking, and accurately handling products on a conveyor by incorporating the advanced Fanuc vision system. This innovation eliminates the need for complex infeed systems, significantly reducing changeover times.

The QP200 is designed for customers seeking an automated solution for products in delicate, flexible packaging within a compact space. It is adept at managing a wide range of products, even with significant handling challenges. By emphasizing flexibility and minimizing the need for mechanical adjustments and frequent changeovers, Quest ensures that each case packing system is fine-tuned to handle diverse SKUs securely and efficiently.

Interactive 3D Animation of the Quik Pack QP200

This interactive 3D animation allows users to explore the intricate workings of the Quik Pack QP200. From its modular design and vacuum tooling that ensures safe, efficient product handling to the innovative QPack HMI software, every aspect is designed to boost productivity.

The animation highlights the system’s intelligent program adaptations, crucial for recognizing product variations and modifying cell operations accordingly. This feature ensures a smooth, uninterrupted production process for meeting high market demands. The visualization also showcases the flexibility of the Quik Pack QP200, including options for flat pack or soldier pack configurations.

When efficiency, reliability, and flexibility are essential, the Quik Pack QP200 offers that and more for innovation in industrial automation. The combination of advanced vision guidance technology, adaptability to a wide range of products, and the ability to handle delicate, flexible packaging makes it a valuable asset for snack food manufacturers looking to scale their operations in line with market growth.