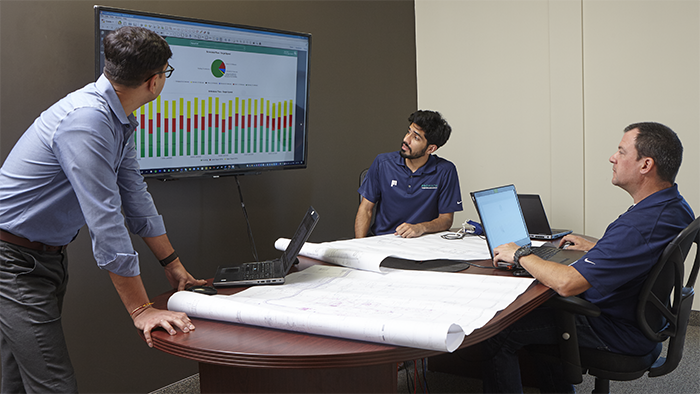

The North American division of a global ready-to-drink-beverage manufacturer began using ZPI’s Monitor & Report in 1999 on a single production line in a single facility and now implements Monitor & Report on over 70 production lines in over 20 filling facilities.

ZPI develops, implements, and supports digital intelligence software-based systems focused on enhancing the performance of packaged goods manufacturing processes by integrating directly onto new or existing production line machinery. ZPI offers four information-based productivity solutions:

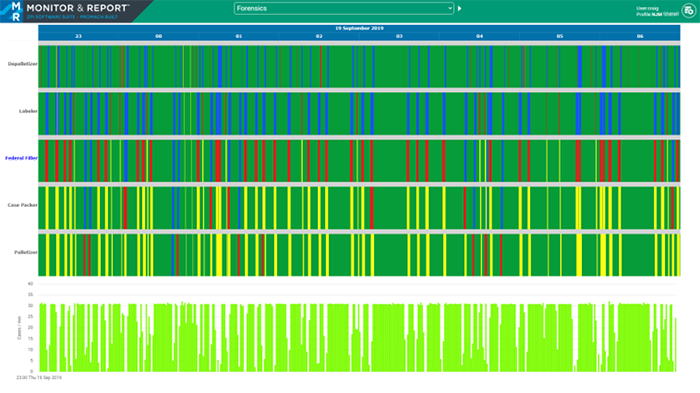

- Monitor & Report: Packaging Line Data Collection & Reporting Software

- Serialize & Track: Product Serialization & Tracking Software

- Maintain & Predict: Packaging Equipment Predictive Maintenance Software

- Professional Services: Subject matter expert consulting and support services

This relationship between ZPI and the global RTD manufacturer spans a twenty-plus year relationship and continues to grow. In order to effectively relay the benefits the customer saw, this case covers the filling line productivity improvements, the time savings at the plant at regional and corporate levels, and the expanded, seamless access to production line and operations data throughout this global business.

Download the case study and read more on how the Monitor & Report software improved the many productions lines of the RTD manufacturer below.